Carbon Black

ASTM Black

ASTM Black refers to a category of carbon blacks produced in accordance with ASTM (American Society for Testing and Materials) standards, ensuring consistent quality and performance across industrial applications. These carbon blacks are designed to provide excellent reinforcement, durability, tensile strength, and resistance to wear and tear.

Reinforcing (Tread) Carbon Blacks

Reinforcing (Tread) Carbon Blacks are high-strength grades specifically engineered to enhance the critical performance characteristics of tyre treads. They significantly improve durability, abrasion resistance, traction, and overall tread life, ensuring tyres can withstand demanding road and driving conditions.

With an optimized particle size and structure, these carbon blacks provide excellent dispersion within rubber compounds, leading to uniform properties, improved processing efficiency, and consistent product quality. Their use helps tyre manufacturers balance grip, wear resistance, and rolling resistance, supporting modern requirements for safety, performance, and improved fuel efficiency.

Semireinforcing (Carcass) Carbon Blacks

Semireinforcing (Carcass) Carbon Blacks are specially developed to deliver a balanced combination of strength, flexibility, and long-term durability in tyre carcass and sidewall compounds. They play a crucial role in enhancing fatigue resistance, allowing tyres to withstand repeated flexing and dynamic stresses during service life.

These grades also help control heat build-up, contributing to improved thermal stability and reduced risk of premature failure under continuous operation. With good dispersion and processing characteristics, semireinforcing carbon blacks enable efficient mixing and consistent compound quality. Their performance supports structural integrity, ride comfort, and reliability across a wide range of tyre designs and operating conditions.

Speciality Black

Speciality carbon blacks have a wide range of functional uses that help manufacturers achieve reinforcement, deep colour, enhanced mechanical strength, improved UV protection, rheology control, and electrical conductivity across various products. These speciality grades are engineered to deliver high performance and consistency, meeting the demanding requirements of diverse applications such as racing tyres, automotive fuel systems, automotive interiors, pressure pipes, power cables, agricultural films, paints, and inks.

Rising tyre performance demands have led to advanced speciality tread blacks that balance grip, rolling resistance, and tread wear more effectively. These next-generation grades offer improved durability, lower rolling resistance, and excellent mixing and dispersion, helping manufacturers achieve modern tyre performance requirements.

- VIRTEX 460

- VIRTEX 800

Engineering plastics such as polyamides, polycarbonates, and other high-performance polymers require pigments that won’t compromise their mechanical properties. Medium-colour speciality carbon blacks provide deep colour at low loadings, ensuring strong aesthetics while maintaining the polymer’s inherent strength and performance.

- Engineering Plastics

- Fibre

- Power Cable

- Films & General Plastics

- Food Contact Blacks

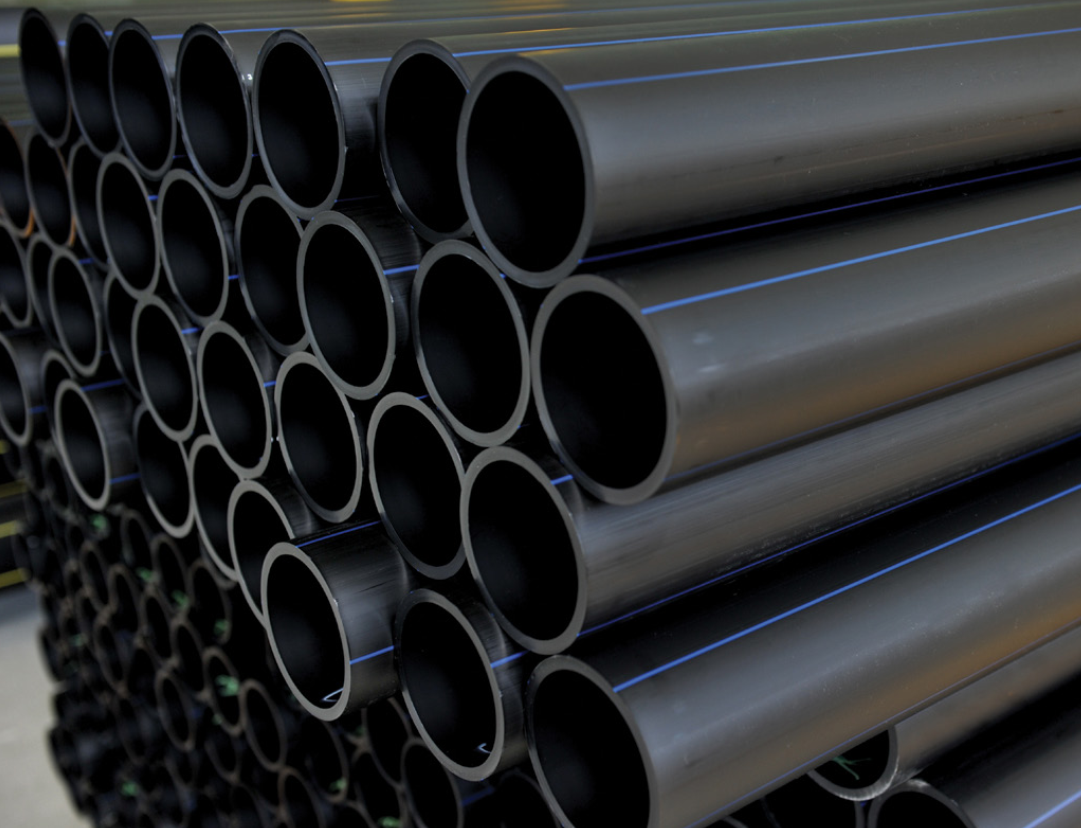

- Pressure Pipes

- Conductive & ESD

Speciality carbon blacks for inks, paints, and coatings deliver deep jetness, stable colour, and a clean blue undertone while meeting strict CIELAB and ink density requirements. They ensure consistent dispersion and rich black aesthetics across printing inks, industrial coatings, powder coatings, and architectural paint formulations.

- Powder Grades

- Treated Grades

- Pellets

Speciality carbon blacks for MRG applications offer low grit, smooth surfaces, and excellent processing for hoses, seals, gaskets, and precision rubber parts. Their clean, uniform structure improves dispersion, reduces defects, and ensures consistent quality through advanced processing and tighter controls than standard ASTM grades.

- KLAREX RG223

- KLAREX RG

- KLAREX RG

- KLAREX RG

- KLAREX RG

- KLAREX RG

- KLAREX RG